Release time:2022-01-24

What is the manufacturing process of insert molding?

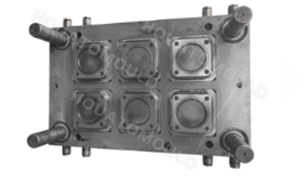

Insert molding is the process of forming thermoplastic materials around preformed parts (inserts) to manufacture parts containing various materials. Inserts are usually metal parts used to enhance the mechanical properties of plastic parts. Place the insert into the plastic mold, and then inject the thermoplastic into the mold to form the part. Compared with installing the insert into the plastic part after molding, the use of molded embedded inserts eliminates the need for secondary installation of the insert, thereby reducing the cost.

Compared with traditional injection molding, what are the advantages of using insert molding?

A typical application of insert molding is to include one or more threaded metal inserts in a plastic part when it is intended to mate with another part in the assembly. The plastic itself may not have sufficient mechanical properties to withstand the forces required to hold the two parts together. For example, threads in plastic parts may be worn out due to repeated use, resulting in part damage. Metal inserts help improve the properties of plastics and ensure reliable fastening when parts are reused. This combination of plastic and metal can take advantage of the lightweight of plastic and the strength of metal.

What are the main design criteria that should be followed when designing insert molded parts?

Like any molded part, typical formability design criteria also apply to insert molded parts, such as increasing the draft angle to help the part demould from the plastic mold and maintain a consistent wall thickness. In addition, some unique factors need to be considered when designing parts for insert molding. For example, the design of undercut features helps to improve the retention strength of inserts in molded parts. Since the insert must be placed in the plastic mold, it is also important to ensure that the insert is located in the accessible area of the plastic mold. Ensuring that the insert is not too deep in the part and that it is fixed in the plastic mold during the molding process also helps to ensure successful results.